Ankur Saxena

Department of Fashion Technology, National Institute of Fashion Technology, Jodhpur- Ministry of Textiles, Govt. of India

Ankita Srivastava

Department of Textile Design, National Institute of Fashion Technology, Jodhpur- Ministry of Textiles, Govt. of India

*Corresponding author: ankur.saxena@nift.ac.in

Abstract

Green manufacturing is the minimization of hazardous matter in the process of designing, production and technology which may affect the domain of the earth and lead towards global warming. It generally refers to broad area including air, water and land pollution, energy usage and efficiency, waste generation and recycling. It is well known fact that production of greenhouse gases (N2O, CO2 and CH4) which are measured to calculate the carbon footprint majorly affect the global warming. Hence to save the environment, it is most significant to decrease the carbon footprint of a sector. Researchers have agreed that one of the main reasons for global warming is industrialization, and green manufacturing can be considered an effective tool to control and minimize the GHG emission from Industries. So this paper will review the application of green manufacturing across the industries including transportation, electricity generation, cement industry, textile and apparel industry etc.

Keywords: Carbon emission, Green manufacturing, Industrialization, Sustainability

DOI: https://doi.org/10.5281/zenodo.6207141

Accepted 16 February 2022

Cite This Article: Saxena, A., & Srivastava, A. (2022). Industry Application of Green Manufacturing: A Critical Review. Journal of Sustainability and Environmental Management, 1(1), 32-45. https://doi.org/10.5281/zenodo.6207141

1. Introduction

The effects of climate change, along with pollution and

the depletion of non-renewable natural resources, have given rise to environmental

awareness (Douglas, 2019). Since the early 20th century, the average surface

temperature of the earth has increased by about 0.8°C, with about two-thirds of

the increase occurring since 1980. Researchers indicate that during the 21st

century, the global surface temperature is expected to rise by a further 1.1 to

2.9°C for the lowest emissions scenario and from 2.4 to 6.4°C for the highest

emission scenario. Climate warming is irreversible and scientists suggests that

most of it is caused by increasing concentrations of Greenhouse gases produced

by activities such as deforestation and the burning of fossil fuels (IPCC, 2020).

In 2014, Greenhouse gas emission was 50 Giga tonnes (Gt.) globally from 196 countries. 5% of total countries were found responsible for more than 85% of the total emission. As per the report by World Resource Institute in 2016, total global emission in 2015 was 43286.2 Mt CO2, out of which more than two third emissions are from top ten countries. In the list of top ten countries, six are developing, and four are developed countries. China topped the list with around 25.36% of global GHG emission. (Juhan, 2015). CO2 emission from China was found at 6.9 Gt. per year followed by United States (5.2 Gt. per year), European Union (2.5 Gt. Per year) and India (1.65 Gt. per year) (IPCC, 2015). Industrialization, energy and agriculture are considered as the major factors contributing more than 80% of the total global emission. To reduce the Greenhouse gas emission and further to minimize the adverse effect on the environment, Green Manufacturing is developed as the essential phenomenon (Nanderi, 2017).

Green Manufacturing is coined to reflect a new

manufacturing paradigm which implements various Green strategies and techniques

to become more efficient (Ariffin, 2015). Researchers have clearly mentioned

that Green Manufacturing is relevant not only from an environmental perspective

but also because of its social and economic aspects (Elkington, 1994;

Kleindorfer, 2015). Green Manufacturing refers to those techniques which

minimizes waste and pollution in manufacturing. It slows down the depletion of

natural resources as well as lowers the extensive amounts of waste that enter

landfills. Green Manufacturing emphasizes on reducing parts, rationalizing

materials, and reusing components yet make the manufacturing more efficient

(Cortellini, 2009). These are manufacturing methods that support and sustain a

renewable way of producing goods and services that do not harm mankind and the

environment. According to another definition, Green Manufacturing covers those

designs, materials, processes and products which are economical and sustainable

while minimizing pollution and risk to human health and environment (Das,

2013).

The value of investing in Green technology and Green

transformation is considered as a topic of argument between researchers and

manufacturers (Deif, 2011). Environmental and Green practices in manufacturing

should move from being an environmental management approach to an environmental

strategy. Following this, manufacturers can improve their environmental

performance while matching economic gains (Hoffman, 2000) (Boston Consultancy

Group, 2009).

Green Manufacturing is required for sustainable

development which also provides competitive advantage to the industries

(Venkatesh, 2015). It is considered that industries which adapt Green

Manufacturing techniques are preferred by the customers. Green Manufacturing

may also be considered as an effective tool for brand building and enhance the

acceptability of any product among the consumers. Hence, manufacturing

organisations are striving hard to adopt the Green practices to get the benefit

of strategic Green Manufacturing in the product management (Adner, 2006;

Gerrard, 2007; Bordoloi, 2008; Tan, 2008). Sustainable and Green Manufacturing

is considered as a future paradigm with the business model based on designing

the environment using nano/bio/material technologies (Jovane, 2003).

2. Methods

The keywords “Industry, Green Manufacturing,

Sustainability and Carbon Footprint” were used to gather the relevant

information about the issue from google scholar.

3. Results and discussion

3.1. Concern towards green manufacturing

The rising levels of Greenhouse Gas (GHG) emission has been increasing concern over the issue among the society, consumers as well as manufactures. The rising issues among different segments towards green has covered in the following sections:

Societal concerns towards green manufacturing

According to Boston Consultancy Group report published in 2011, the

society’s rising concern for Green can be grouped into three broad categories.

Rising emissions and associated climate change is termed as the first category.

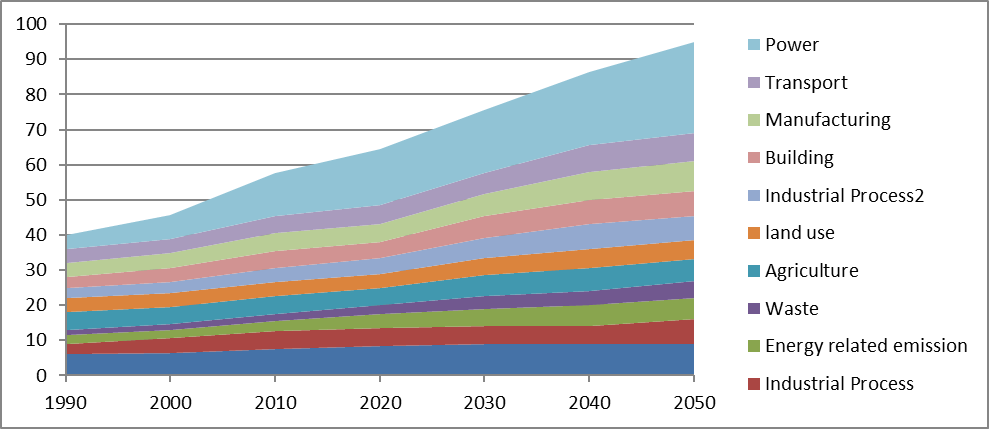

Figure 1 shows the expected increment in GHG emission in different sectors by

2050. This could mean that by the end of this century corresponding temperature

may rise up to 4-6°C over pre-industrial levels. This unprecedented change is

expected to have a huge impact on the global ecosystem, hydrological system,

sea level, crop production and related activities.

Figure 1: Expected

Greenhouse gas emissions by 2050 in different segments

Fast depletion of scarce natural resources was considered as the second category of societal concern towards Green. With ever increasing population and industrialization, the consumption of natural resources (example: wood, coal, oil, food, water, etc.) is rapidly on the rise, while their availability is shrinking. This has led to periodic mismatch in demand-supply with highly fluctuating prices, impacting both corporate margins and consumer spending. There is an urgent need to (a) adequately manage the use of these resources and (b) find and develop alternatives which are less scarce (example: wind, sun). Growing waste generation and pollution was considered as the third category according to which increased industrialization and urbanization have led to significant growth in waste generation and environmental pollution. Industrial waste with chemical composition can be potentially dangerous to health, and its disposal without treatment is leading to land and water pollution. The release of industrial effluents in rivers and other water bodies is destroying local habitats. As the demand and use of electronic products rise, e–waste is also becoming a major source of environmental pollution.

Consumer perspective towards green manufacturing

Green Manufacturing is indispensable, not just due to

tightening regulations or cost benefits, but also because consumers are

demanding it. (Massachusetts Institute of Technology, 2010). Researchers

believe that through purchasing Green products and products with recyclable packaging,

consumers can contribute significantly to improve the quality of the environment

(Abdul-Muhmin, 2007).

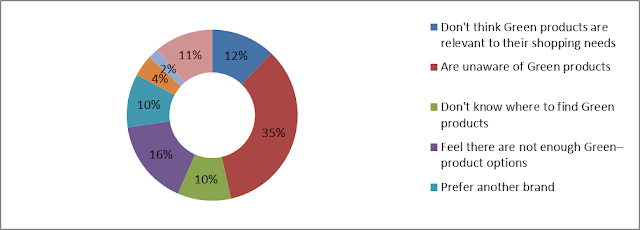

Figure 2: Barriers of Green products

In an interesting survey conducted by Chen & Chai in Malaysia in 2010 it was observed that gender does not play significant role in their environmental attitudes and their attitudes on Green products (Chai, 2010). However, many studies have shown the significant differences between men and women in environmental attitudes (Brown, 1992) (Tikka, 2000).

Industry perspective towards green manufacturing

In a survey conducted by BCG and MIT in 2009, around 1560 companies were interviewed about possible benefits of Green Manufacturing. Executives of nearly all the companies interviewed said that sustainability-related issues have or will soon have a material impact on their business (Boston Consultancy Group, 2009). Figure 3 shows the responses recorded during the survey. Findings of the survey confirm that Green Manufacturing may be used as an effective tool in brand building and help companies getting an edge over its competitors.

As per Dobers and Wolff, Financial institutions increasingly value companies according to their social and environmental practices. The opportunity for companies to use Green practices to improve their reputation and strengthen their position in the marketplace constitutes the business case for Green Manufacturing (Dobers, 2000). In a similar way, potential strategic partners, such as government agencies, suppliers, banks and other lenders, currently appear much more sensitive to social and environmental performance when selecting companies for alliances (Miles, 2000).

3.2. Application

of green manufacturing in different segments

Considering the broad definition of Green Manufacturing, different sectors are adopting Green practices as per their requirements and convenience. Application of Green Manufacturing in different sectors like transportation, agriculture, electricity generation, textiles etc. is as follows:

Green manufacturing in transportation

Green

transportation is the term which is being used by the researchers for reducing

GHGs emission from the transportation sector. As the transportation sector is

responsible for carrying goods and passengers, it is considered as the

foundation for industrial setup. This segment is responsible for approximately

15% of overall GHG emissions. Also, it accounts for approximately 23% of

overall CO2 So, it will ultimately worsen the scenario of GHGs emission in the

environment (Lipman, 2007). In a study, Sukarno et al. developed a system

dynamics model focusing on road transport in Indonesia, which predicted that

total fuel consumption and road emission from this sector may 62 and 65 times

higher in next couple of years as compared to the level in 2013 (Sukarno,

2016). These data show that the sector needs immediate attention from the

researchers and industries worldwide to reduce its negative impact on the

environment.

Table 2 shows the contribution of various transport segments in overall GHGs emission. It is clear from the table that road transportation is primarily responsible for GHG emission among other mediums as this segment is mainly used by the industries for transportation activities.

Table 1: Contribution of

transport sector in Greenhouse gases emission

|

Transportation Sector |

Global Share |

|

Road |

9.9 % |

|

Air |

1.6% |

|

Rail, ship and other Transportation |

2.3 % |

|

Total Contribution |

13.8 % |

Improvement in engine technology and fuels, Intelligent Transportation Systems (ITS) and mobility management are among the few most important strategies to deal with this burning issue (Lipman, 2007). Evangelista et al. also described the importance of third party logistics in improving Green Manufacturing in industries through their exploratory case study analysis. It was observed that environmental regulations act as a major driving force for the industries to adapt Green manifesting initiatives as this ultimately results in fuel cost reduction and recycling (Pietro Evangelista, 2010). Cosimato et al. 2014) also found with their DHL case study in Liverpool that environmental regulations would be beneficial for economic growth. They observed Green practices in DHL results in competitive advantage, cost saving, better product quality, increased efficiency and productivity (Cosimato, 2014.).

Green manufacturing in electricity generation

Dependence of

electrical power generation on fossil fuel (coal, natural gas and oil) is

responsible for great amount of GHGs emission which leads to climate change.

This scenario paves the way for the concept of sustainable energy, where energy

is extracted, converted and utilized sustainably to minimize the environmental

damage. Hydropower has been found as one of the most efficient sustainable

technology for power generation. Though, relatively high investment cost and

associated risk are the drawbacks of this technology (Kaunda, 2012).

To analyze the socio-economic impact of various power generation methods in Ontario, Canada, Dampier et al. reviewed the literature related to the same. They found that although Ontario is moving towards the non-coal electricity generations operations to reduce the GHGs emission; some other countries such as USA, Denmark, Finland, Germany and Belgium are opting for the concept of co-firing, where electricity is generated through burning coal along with woody biomass. Figure 4 shows the changes in electricity generation trend from different sources from 2003 to 2011. It is noted that while electricity generation from nuclear and hydro sources remains relatively constant, usage of coal has decreased significantly for electricity generation. It should also be noted that gas, wind and some other alternative sources have marked their presence to fulfill the purpose (Dampier, 2013).

Figure 4: Historical

changes in fuel supply used for electricity production from 2003 to 2011

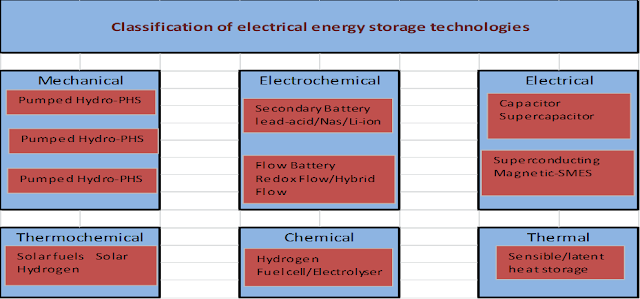

In a recent study, Luo et al. overviewed the electrical energy storage (EES) systems which can store the energy in various forms, according to the technology used, and convert it into electrical energy when needed. Six major categories were chosen for the study as shown in Figure 5:

Figure 5: Classification

of EES technologies by the form of stored energy

Source: (Xing Luo, 2015)

It has been found that deployment of specific EES technology in a certain segment depends on several factors including technological maturity, reliability and potential environmental impacts, investment cost and the economic gain. Combinations of different EES technologies can also be considered as an effective tool depending on the requirement of the sector (Luo, 2015). Jacobson et al. suggested that with continuing effort, alternative resources such as wind, water and sunlight can replace the existing systems of power generation and reduce GHGs emission significantly (Jacobson, 2011).

Green manufacturing in agriculture activities

As per Vermeulen et al. (2012), CHG emissions are divided into two major categories in context of agriculture emission, direct through agriculture practices and Indirect through land-cover change emission. It was found that direct agriculture activities majorly emit N2O and CH4 and very less amount of CO2. Whereas, land-cover changes, to open new land for agriculture activity by deforestation, majorly cause CO2 emission. One must consider these factors to work towards limiting the emissions in agricultural segment (Vermeulen, 2012). In a recent study done by Teague et al., they observed that right cropping and grazing practices can preserve the soil organic carbon (SOC) of soil and minimize the soil erosion. In that way despite responsible for GHGs emission, soil may act as sink for GHGs (Teague, 2016).

Green manufacturing in household activities

Analysis of environmental impact due to household activities has been the critical area of concern for the researchers. It has been found that critical part of the study includes different sizes of households, their income and expenditure patterns which make it difficult to standardized the theories. Weber et al. focused their study on the household activities in US and their respective CO2 emission considering their global and distributional aspects. Thirteen most common categories for household activities have included in the study. The result is shown in figure 6. It was also observed that nearly 30% total US household emission in 2004 occurred outside the US (Weber, 2008).

Figure 6: Total household expenditure in 2004 (Red bar) and CO2 emissions (Mt/yr) from household consumption in 13 consumption categories

Shirley et al. have developed a carbon footprint calculator for household activities in Virgin Island of The United States. Average carbon footprint in the territory was calculated as 13 tCO2e per year per capita which was approximately 35% less than the average carbon footprint of United States. It was also observed that electricity and food were mainly responsible for carbon footprint. The carbon footprint was calculated by using Process Analysis and Economic Input Output (EIO) method. Life cycle assessment (LCA) was used to calculate Greenhouse gas (GHG) emissions during the various phases of commodities including their consumption by households. Figure 7 represents the Carbon di oxide emission due to various household activities which shows that Home energy was majorly responsible for the emission followed by transportation and food (Shirley, 2012).

Figure 7: Carbon di oxide gas emissions from different household activities in United States Virgin Island

Green manufacturing in industrial application

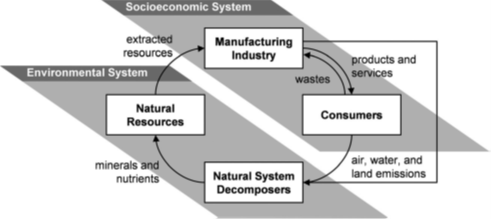

Manufacturing industries consumes natural resources and energy and emits major amount of total GHGs emission which are ultimately responsible for global warming and climatic changes (Mittal, 2014). To reduce the effect of Greenhouse gas emissions and thus improve the overall environmental effects on product life cycle, industries are approaching towards Green Manufacturing. To obtain this phenomenon, several tools and metrics have been developed by the researchers to measure the environmental impact of a product life cycle. Carbon footprint is considered one of the prominent ways to quantify the climate change impact of GHGs emission. Life Cycle Assessment is another tool which is used by the industries which cover all the processes related to a product or a service which helps to assess all the environmental impacts of the system, in contrast to the CFP where only contributions to climate change have been assessed (Finkbeiner, 2009; Cucek, 2012).

Figure 8: The role of the

manufacturing industry in a sustainable system

The industrial

sector currently accounts for about one-half of the world’s total energy

consumption and the consumption of energy by the sector has almost doubled over

the last 60 years. Furthermore, industrial energy consumption is expected to

increase 40% from 175 quadrillion Btu in 2006 to 246 quadrillion Btu in 2030.

Given mounting concerns related to climate change, manufacturing enterprises

are facing growing pressure to reduce their carbon footprint. This pressure

will become even more significant in the future due to the increasing cost of

energy, resulting from both likely taxes and regulations related to carbon

emissions as well as increasing energy demands from developing countries. These

environmental and economic factors provide motivation for substantial

initiatives directed at minimizing energy consumption and GHGs emissions from

manufacturing enterprises (Fang, 2011).

In a related study conducted in India by Ramachandra et al. identify the sectors and regions for carbon emission (CO2, CH4 and CO) and carbon sequestration capacity. Among other sectors, cement and steel industries were found as a major source of industrial CO2 emission. The total CO2 emission from India was recorded 965.9Tg/year where cement and steel industries alone contributes 202.2Tg/year although CH4 and CO emission was found nil.

Figure 9: Sector wise

contribution on total carbon emission in India

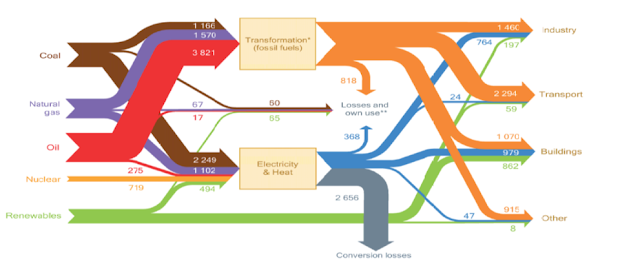

In an analysis done by Laurent et al., they compared the effect of CFP and Human Toxic Impact (HTI). A poor correlation was observed between the CFP and HTI for major materials used in industries like metals, plastics, textiles etc. This indicates that for a detailed analysis, effect of GHGs on overall environmental impact should be observed case-by-case basis (Laurent, 2011). As per a report published by International Energy Agency in World Energy Outlook 2012, Industry, transport and building shares almost equally in terms of GHGs emission and energy consumption as shown in Figure 9 (United Nations Industrial Development Organization, 2014).

Figure 10: Energy consumption and Greenhouse gas emission by industry, transport and buildings

In a study by

Mittal et al. (2014) drivers or motivating factors were identified and ranked

according to their importance in implementation of Green Manufacturing in

industrial segments. It was found with fuzzy TOPSIS method that incentives

ranked at top position followed by public pressure, legislations and public

image as among the other important factors. Hence it was concluded that

encouragement from government in terms of incentives to the industries and firm

policies towards green manufacturing may play a vital role for implementation of

Green Manufacturing in industries (Mittal, 2014). In another study by K.

Govindan it was found by using fuzzy AHP approach that Government legislations

ranked top among some other important drivers.

Following sections present green manufacturing systems incorporated in major industrial segments to study the present scenario and future requirements in these areas.

Cement industry

Being a basic

construction material, cement contributes nearly 5% to the worldwide CO2

emission. According to estimation by 2050 cement plants may produce 5 billion

tonnes of CO2 globally. Thus, CO2 emission in the cement industry, which cannot

be ignored because of the inherent chemistry of cement, has a significant

impact on climatic change. Cagio et al.

have done a study on calculation of carbon footprint in cement industry. They

have MC3 Methodology, the Composed Method of Financial Accounts in its second

version V.2.0, was used in this work to calculate the carbon footprint. The

study was based on the analysis of three model plants of cement industry, a

conventional integral plant, a grinding plant, and an integral plant which has

introduced the best available techniques (BAT) into the manufacturing

process. Finally, the first two plants

were compared for their CO2 emissions with the third plant and it was found

that CO2 emissions were reduced significantly with the BAT plant. The authors

also insisted that increasing social awareness towards Green Manufacturing is a

necessity as economic issues are still the major constraint among the

industries. Hence, analysis should be done at the design stage only to compare

the carbon footprint emission with different raw material and techniques to

obtain the most sustainable option (Cagiao, 2011).

According to a report published in 2014 under Industrial Development Organization, United Nations, clinker being the main ingredient of cement is majorly responsible for the high CO2 emissions and energy usage in this segment as it is produced by sintering limestone and clay. Studies suggest that alternative raw material and fuels, alternative techniques in crushing and grinding raw materials, energy-efficient technologies in manufacturing and more use of blends to reduce the amount of clinker are the key areas which can promote the green manufacturing in this segment while reducing the energy consumption and wastage (UNIDO, 2014). Apart from this, industrial byproducts and waste such as red mud, bottom ash and fly ash can also be utilized in the cement production process to make the process more energy efficient (Potgieter, 2012; Benhelal, 2012). A study carried out in a firm in Kenya from 2011-2014 also confirms that alternative fuel and techniques can significantly reduce the GHGs emission. Authors also insisted on enforcing the environmental laws and regulations for adaption of Green Manufacturing practices in industry (Eshikumo, 2017).

Textile and garment manufacturing

The textile

industry significantly affects the environment by releasing carbon dioxide into

the atmosphere. The weaving and spinning sector contributes a lot to emission

in carbon dioxide. However, the apparel sector contributes 3-4% of overall

emission and is rapidly increasing (Mehta, 2014). A study conducted in India deduced that garment

manufacturing plays a vital role not only in the country’s economy but also in

the lives of millions of people of the country. The apparel Industry, along

with textiles contributes almost 33% of the country’s exports (Advisors, 2015).

Apart from providing one of the necessities of life, the textiles industry also

contributes about 15% to industrial production, 4% to the GDP, and 17% of the

country’s export earnings. It provides direct employment to over 35 million

people (Ministry of Textiles, 2016).

In the context

of global apparel Industry, Eryuruk et al. (2012) has calculated carbon

emission during a lifecycle of an apparel product. He has divided the life

cycle from design to reuse and calculated emission for each process. Author has

also identified the types of waste generated in every step of the process. It

was deduced that taking precautions at each and every stage of apparel

manufacturing is important for sustainable production. (Eryuruk, 2012). Wu et

al. have presented a model for Taiwan textile and apparel industry in which

drivers for Green supply chain management were identified as organizational

support, social capital and government involvement (Wu, 2014).

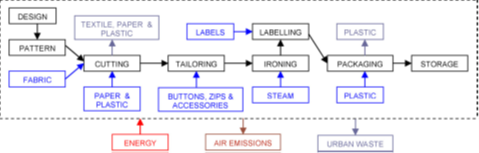

In continuation to the studies based on Green Manufacturing in garment manufacturing industry, Herva et al. developed a tool for evaluating the environmental impact due to the performance of a cotton jackets manufacturing plant. Different tailoring processes were compared in this research for their environmental behavior. The manufacturing data were divided into three parts; resource, energy and wastage to understand their contribution in ecological footprint, where the first two are consumed while the third one is generated during the process. Main resources used in the industry were cotton fabric, lining and stitching material, plastic, paper and cardboard etc. It was found that the material used in manufacturing the jackets is the major contributor in ecological footprint. Energy was found as the second contributor followed by waste generated during the process. Figure 2.12 shows the process flow diagram of the jacket manufacturing unit (Herva, 2008). Therefore, it can be concluded that material should be chosen wisely as ecological footprint may change by varying the material used during manufacturing the garment.

Figure 11: Jacket manufacturing factory process flow sheet

In a subsequent

study by the authors, two different environmental evaluation methodologies,

energy and materials flow analysis (EMFA) and ecological footprint (EF), were

applied for a detailed analysis of the material and energy flow. It was

observed that cutting is the most energy consuming stage in the manufacturing

process of a jacket. Also, gas-oil was identified as an important source of

pollution though the contribution in energy supply was low so they recommended

using a substitute to minimize the negative effects on environment (Herva,

2012).

Globally the

response by researchers in the field to increased production and consumption is

diverse and ranges from discussions about systems change at the manufacturing

level to notions like cradle to cradle (McDonough, 2008), Cradle to grave, slow

fashion (Kate, 2007), dematerialization, zero wastage, Green Manufacturing and

eco design among others (Timo, 2008). However, while proposed models vary,

there is agreement on the fact that textile reuse offers very large carbon

benefits and even the recycling of textiles is second only to aluminum

recycling in terms of carbon benefits, compared to recycling of all other

wastes in municipal solid waste (Woolridge, 2006).

Reuse and

recycling of clothing results in a reduction in the environmental burden

compared to purchasing new clothing made from virgin materials. In a UK based

study, Woolridge et. al (2006) quantified and compared the energy used by a

reuse/recycling operation and estimated a saving for every kilogram of virgin

cotton displaced by second hand clothing at approximately 65 kWh and for every

kilogram of polyester at around 90 kWh, using a streamlined Life Cycle Assessment

for energy consumption. The reuse of one ton of polyester garments only

consumes 1.8 % of the energy required for the manufacture of goods from virgin

materials and the reuse of one ton of cotton clothing only uses 2.6 % of the

energy required to manufacture those from virgin materials. The textile

industry is estimated to use 378 billion liters of water annually, using up to

200 liters of water to process, dye and finish each kilogram of textiles

(Woolridge AC, 2006).

Green and

Sustainable practices in H&M were studied by Bin Shen (Bin Shen, 2014).

Author has shown his concern regarding the tendency of recognized apparel

brands, who are taking advantage of lesser environmental awareness and relaxed

environmental regulatory systems of developing countries that leads to lesser

manufacturing cost. But H&M has recognized the fact that consumers are more

educated about the social and environmental consequences because of their

purchases and so cost should not be the only factor to choose their manufacturing

base. H&M and their vendors have adopted green practices to make their

business more Sustainable.

Several researchers have discussed about evaluating present Green Manufacturing practices in different departments of global apparel and textiles industry (Baskaran, 2014; Ngai, 2014; Caniato, 2015). Battaglia et al. has mentioned the huge impact of fashion and apparel industry on environment. They have also discussed the importance of sustainabilitiy issues which are crutial to the apparel and fashion industry (Battaglia, 2014). There are studies which suggest that consumers are interested in Green products and also ready to pay higher price for such products (Shen, 2012). Due to consumer’s increasing awareness about environment, Green and sustainable products are significantly inportant and have a critical role to play in textile and garment sector.

Coal mines

It is considered

that the coal is the primary source of energy and consumption of world coal is

growing on an average of 1.1% per year from 2007 to 2020, and will continue to

grow with 2.0% per year from 2020 to 2035. The emissions from coal mine contain

significant amounts of methane (0.1-1%) which has Global Warming Potential more

than twenty times higher than CO2. Also, methane emissions from coal mines

account for 22% of emissions from energy sector.

Considering the facts, a study was carried out by Diaz et al. for analyzing the carbon and ecological footprints for coal mine ventilation air. The study was conducted on the coal mine situated in Asturias (North of Spain), which belongs to the Spanish mining company (HUNOSA). It was found that the most important contribution to environmental impact of the coal mining extraction was due to the ventilation of gases generated in the shafts. Results indicate that the implementation of commercial technologies for the treatment of these emissions can lead to significant decrease in methane emission thus reducing the carbon footprint up to 70% (Eva Diaz, 2012). Figure 10 shows the comparative data of emission of gases with carbon foot print and ecological footprint and it is clearly seen that the percentage of methane reduce significantly with ecological footprint.

Figure 12: Environmental

impact of coal mining (bituminous, Spain): carbon (CF) and ecological (EC)

footprints

Automotive Industry

Automotive

industry is considered as one of the most important source of Greenhouse gas

emission due to its size, expansion, diversity, importance and inter-dependency

between the industry and other sectors. Considering the importance of its

environmental impact, major car manufacturers such as Toyota, GM and Volkswagen

are adopting Green initiatives in main sectors of manufacturing which includes

Green buildings in providing the facilities, eco-design in product development,

Green Manufacturing practices for production, Green supply chain for supplier

relationship and logistics, reverse logistics for after sales and backwards

flow of materials etc. (Wells, 2007; Bennett B. N., 2009). The environmental initiatives taken by major

car manufacturing companies are mainly concerned towards environment friendly

manufacturing processes, product performance, supply chain management,

non-manufacturing facilities to final disposal of the product.

A further in-depth analysis shows that companies are moving from being reactive to proactive and extending control over all related activities in the supply chain and taking their decisions accordingly. It is suggested that companies, who want to achieve the environmental goals, should focus on the whole operations functions rather than taking care of isolated activities (Bennett, 2010). Table 3 shows the simplified car life cycle environmental impact (Martinuzzi, 2011).

Table 2: Car life-cycle

impact on environment

|

Preassembly

Phase |

Assembly

Phase |

Use Phase |

Post Use

Phase |

|||||||

|

Raw material

Extraction, Production of secondary materials and their transportation,

production of components and subassemblies |

Energy use,

pollution in assembly processes especially paint shop, release of waste

material into grounds, water, transportation of carts to customers |

Energy used

for driving, pollutions emitted, waste (batteries, tires, oil) land use

requirements, fuel stations, road and parking places |

transportation

to dismantling sites, energy used, pollution caused by dismantling |

|||||||

Certainly, the designing of car is the most important factor towards environmental friendly manufacturing which helps to decide the material, process, usage and leads to the sustainable end-of-life techniques. According to Sarkis et al. proper training programs for the automotive companies is essential to motivate them towards eco-designing and handle the pressure of stakeholders (e.g. governmental or regulatory agencies) for fulfilling the environmental regulations (Sarkis, 2010).

4. Conclusion

Present review

paper provides the insight of current scenario of Green Manufacturing in

various segments with an emphasis on industrial application. Green

manufacturing involves the control of environmental factors which can adversely

affect the environment. The alarming situation of global warming has caused

both researchers and practitioners to devote attention towards the impact of

GHGs emission on the environment. However, a concrete analysis of the problem

is missing, even though significant research work has been done in studying the

impact and reduction of carbon footprint in different manufacturing industries.

It can be concluded that Green initiatives must be taken at every stage

starting from the design to manufacturing and application of products or processes.

Awareness towards Green should also be improved among both manufacturer and

consumers through different government initiatives, strict regulations and

policies to enhance the Green Manufacturing initiatives.

References

A.

Laurent, S. I. (2011). Carbon footprint as environmental performance indicator

for the manufacturing industry. CIRP Annals - Manufacturing Technology, 59,

37-40.

A.

Nanderi. A. (2017). Productive design a new design attitude. APO World

Conference on Green Productivity.

Abdul-Muhmin,

A. (2007). Exploring consumers’ willingness to be environmentally friendly. International

Journal of Consumer Studies, 78-86.

Acharya,

S. G. (2014). A review on evaluating green manufacturing for sustainable

development in foundry industries. International Journal of Emerging

Technologies and Advanced Engineering, 83-92.

Adner,

R. (2006). Evaluation of sustainable development in manufacturing industries. Journal

of cleaner Production, IV, 101-110.

Ahuja,

V. Y. (2009). Benefits of collaborative ICT adoption for building project management.

Journal of Construction Innovation, 9, 142-156.

Andre

Martinuzzi, R. K. (2011). CSR activities and impacts of the automotive sector. RIMAS

Working Papers, 3/2011, 128-140.

Baskaran,

V. (2014). Indian textile suppliers' sustainability evaluation using the grey approach.

International Journal of Production Economics, 647-658.

BCG.

(2009). What’s next for Alternate

Energy?. BCG.

Bennett,

B. N. (2009). Green technologies in the automotive industry. International

Association for Management of Technology, 192-107.

Bennett,

B. N. (2010). Green operations initiatives in the automotive industry: An

environmental reports analysis and benchmarking study. Benchmarking: An

International Journal, 17(3), 396-420.

Bhattacharya,

A. (2011). Green manufacturing:

Energy, product and processes. Mumbai: Boston Consultancy Group.

Bordoloi,

S. A. (2008). Design for control: A new perspective. International Journal

of Production, III, 346-358.

Boston

Consultancy Group. (2009). The

sustainibility initiative. BCG and MIT. Boston: BCG and MIT.

Boston

Consultancy Group. (2009). The

sustainibility initiative. Boston Consultancy Group. UK: Boston

Consultanct Group .

Brown,

G. a. (1992). The US forest service: Toward the new resource management paradigm?

Society and Natural Resources, 5, 92-99.

Cai,

J.-y. L.-j. (2014). An optimization model based on electric power generation in

steel industry. Mathematical Problems in Engineering, 29-38.

Caniato,

F. (2015). Environmental sustainability in fashion supply chains: An

exploratory case based research. International Journal of Production

Economics, III, 659-670.

Chai,

T. B. (2010). Attitude towards the Environment and Green Products. Management

Science and Engineering , Vol.4 No.2, 87-104.

Chattopadhyay,

S. (2015). Efficiency of Indian Garment Manufacturing Units in the Post MFA

Period. The Journal Of Industrial Statistics, 58-75.

Chien,

M. K. (2007). An empirical study of the implementation of green supply chain

management practices in the electrical and electronic industry and their

relation to organizational performance. International Journal of Environment

Science, 143-152.

Chiyembekezo

S. Kaunda, C. Z. (2012). Hydropower in the context of sustainable energy

supply: A review of technologies and challenges. ISRN Renewable Energy,

120-135.

Christopher

L. Weber, H. S. (2008). Quantifying the Global and Distributional Aspects of

American Household Carbon Footprint. International Journal of Ecological

Economics, 379-391.

Chung,

C. A. (2010). Green-product-design value and information-technology investment

on replenishment model with remanufacturing. International Journal of

Computer Integrated Manufacturing, 466-485.

Cortellini,

R. (2009). Green design approaches in different sectors. International

Journal of Innovation, II, 37-43.

Cranstona,

G. (2012). Carbon footprints in a bipolar, climate-constrained world. Ecological

Indicators, 16, pp. 91-99.

Das,

M. (2013). Performance measurement of green manufacturing criteria of Indian

SME,s. International Journal of Engineering Research and Technology,

2913-2920.

Deif,

A. M. (2011). A system model for green manufacturing. Journal of Cleaner

Production, III, 153-159.

Dermot

J. Roddy. (2012). A syngas network for reducing industrial carbon footprint and

energy use. International Journal of Applied Thermal Engineering, 11-16.

Devaraja,

D. (2012). Indian textile and garment

industry. New Delhi: Indian Council of Social Science- Ministry

of HRD, Govt. of india.

Dobers,

P. &. (2000). Competing with “soft” issues - From managing the environment

to sustainable business strategies. Business Strategy and the Environment,

9(3), 143-150.

Douglas,

J. (2006). Building adaptation.

Newyork, USA: Butterworth-Heinemann.

Elkington,

J. (1994). Towards the sustainable corporation: Win–win–win business stratigies

for sustainaible development. California Management Review, 90-100.

Eryuruk,

S. H. (2012). Greening of the Textile and Clothing Industry. FIBRES &

TEXTILES in Eastern Europe. London: AMG Publications.

Eva

Diaz, J. F. (2012). Carbon and ecological footprints as tools for evaluating

the environmental impact of coal mine ventilation air. Ecological

Indicators, 18, 126–130.

Farris,

D. (1975). Use of interpretive structural odeling for worth assessment’,. Computers

and Electrical Engineering, 2(5), 306-316.

Galli,

A. W. (2012). Integrating ecological, carbon and water footprint into a “footprint

family” of indicators: definition and role in tracking human pressure on the

planet. Ecological Indicator.

Gerrard,

J. a. (2007). Is European end-of-life vehicle legislation living up to

expectation? Assesing the impact of the ELV directive on green innovation and

vehicle recovery. Journal of Cleaner Production, 3, 17-27.

Gustavo

G. T. Camargo, M. R. (2014). Energy use and greenhouse gas emissions from crop

production using the farm energy analysis tool. International Journal of Bio

Science, 263–273.

Hawthorne,

R. W. (1975). Applications of interpretive structural modeling to higher

education program planning. Socio-Economic Planning Sciences , 9, 3-143,

54-58.

Herva,

M. (2011). An approach for the application of the ecological footprint as

environmental indicatorin the textile sector. Journal of Cleaner Production,

67-76.

Hoekstra,

A. (2008). Value of water research report

the impacts of water footprints. Netherland: UNESCO-IHE, Delft.

Hoffman,

A. (2000). Competitive Environmental Strategy. International

Environmental Agency, International Environmental Agency. chicago: Island

Press.

huberman,

M. &. (1994). Quantitative Data Analysis (Vol. 6(3)). Newyork: Sage

Publication.

Indian

Brand Equity Foundation. (2017). Textile Industry & Market Growth in

India. New Delhi: Indian Brand Equity Foundation.

International

Energy Agency. (2008). World Energy Outlook.

IPCC.

(2008).

IPCC.

(2009). Expert Meeting on the Sciences

of Alternative Metrics. International panel of climate control.

Oslo, Norway: IPCC.

IPCC.

(2015). Climate change and resource sustainability-

an overview of actuaries. Canada: International Panel of Climate

Control.

Iwan

Sukarno, H. M. (2016). Transportation energy consumption and emissions - A View

from City of Indonesia. Future Cities and Environment, 2-6.

Jadhav,

J. R. (2013). Interpretive structural Modeling for implementation of integrated

green-lean system. International Journal of Computer Applications, 0975

– 8887.

Jason

Ernest Elvin Dampier, C. S. (2013). From coal to wood thermoelectric energy

production: A review and discussion of potential socio-economic impacts with

implications for northwestern Ontario. Journal of Sustainibility and Society.

Joseph

Sarkis, P. G.-T.-D. (2010). Stakeholder pressure and the adoption of

environmental practices: The mediating effect of training. Journal of

Operations Management, 28, 163–176.

Jovane,

P. (2003). Present and future of flexible automation. Centre for

International Research and Policy (CIRP) Annual, 543-560.

Juan

Cagiao, B. G. (2011). Calculation of the corporate carbon footprint of the

cement industry. Journal of Cleaner production, 3, 192-202.

Juhan

friedrich, M. G. (2015). Infographic:

What do your country's emissions look like? Oslow: Worls Resourse

Institute.

Kan

Fang, N. U. (2011). A new approach to scheduling in manufacturing for power

consumption and carbon footprint Reduction. International Journal of

Manufacturing Systems, 30, 234– 240.

Kannan,

G. (2010). Analyzing supplier development criteria for an automobile industry. Industrial

Management & Data Systems, 43-62.

Kate, F. (2007 йил 1-June). Slow fashion.

The Ecologist, pp. 32-36.

Khodakaram

Salimifard, H. S. (2012.). Green transportation and the role of operation research.

International Conference on Traffic and Transportation Engineering.

Kleindorfer,

P. (2015). Sustainable operations management. Production and Operation

Management, 482-492.

Laurent,

A. (2010). Carbon footprint as environmental performance indicator for the

manufacturing industry. CIRP Annals - Manufacturing Technology, 59,

37-40.

Lidija

Cucek, J. J. (2012). A review of footprint analysis tools for monitoring impacts

on sustainability. Journal of Cleaner Production, 34, 9-20.

Lipman,

S. A. (2007, August 26). Reducing greenhouse emissions and fuel consumption –

Sustainable approaches for surface transportation. IATSS Research, 31 (1),

pp. 26-35.

Liu,

F. Y. (2005). Investigations and practices on green manufacturing in machining

systems. Journal of Central South University of Technology, 12(2),

18-24.

Liu,

H. C. (2005). Fuzzy multiple decision making for evaluating aggregate risk in

green anufacturing. Tsinghua Science & Technology, 10(5), 627-632.

M.

Battaglia, F. T. (2014, August 21). Corporate social responsibility and competitiveness

within SMEs of the fashion industry: Evidence from Italy and France. Sustainibility

2014, pp. 872-893.

M.

Finkbeiner. (2009). Carbon footprinting-opportunities and threats. International

Journal of Life Cycle Assessment, 91-94.

M.

Herva, A. A. (2012). Combined application of energy and material flow analysis

and ecological footprint for the environmental evaluation of a tailoring factory.

Journal of Hazardous Materials, 237-238.

M.

Herva, A. F. (2008). An approach for the application of the ecological

footprint as environmental indicator in the textile sector. Journal of

Hazardous Materials, 156, 478-487.

Mark

Z. Jacobson, M. A. (2011). Providing all global energy with wind, water, and

solar power: Technologies, energy resources, quantities and areas of

Infrastructure, and Materials. Journal of Energy Policy, 1154-1169.

Massachusetts

Institute of Technology. (2010). Lightspeed Research Global Survey.

Newyork: Massachusetts Institute of Technology.

McDonough, B. (2008). Cradle to Cradle:

Remaking the Way We Make Things. San Fransisco: North Point Press.

Md.

Salman Alvi, S. A. (2013). Approaching Green Manufacturing In Iron And Steel

Industry. International Journal of Mechanical Engineering and Robotics

Research, 2(3), 125-134.

Mehta,

M. V. (2014). Emerging issues in Apparel Trade. Apparel Export Promotion

Council. Delhi: Apparel Export Promotion Council.

Miles

M. P., C. J. (2000). Environmental Marketing: A Source of Reputational,

Competitive, and Financial Advantage. Journal of Business Ethics, 23(3),

299-311.

Minhaj

Ahemad.A.Rehman, ,. R. (2013). Validating Green Manufacturing (GM) Framework

for Sustainable Development in an Indian Steel Industry. Universal Journal

of Mechanical Engineering 1(2), 49-61.

Ministry

of Textiles. (2016). Annual Report-2016. New Delhi: Ministry of

Textiles- Govt. of India.

Ministry

of Textiles. (2016). Annual Report-2016. Ministry of Textiles. New

Delhi: Ministry of Textiles.

Mishra

S., D. S. (2012). Inter Relationship of Drivers for Agile Manufacturing: An

Indian Experience. International Journal of Services and Operations

Management, 11, 95-106.

Murray,

T. J. (1985). A Pilot Study of Fuzzy Set Modification of Delphi. Human

Systems Management, 5,, pp.76-80. .

Ngai,

E. (2014). Development of the Conceptual Model of Energy and Utility Management

in Textile Processing: A Soft Systems Approach. International Journal of

Production Economics, 607-617.

Pietro

Evangelista, E. S. (2010). Green Supply Chain Initiatives in the Transport and

Logistics Service Industry: An Exploratory Case Study Analysis. Proceedings

of the 14th Annual Conference of the Logistics Research Network (pp.

195-203). Leeds: Logistic Research Network.

Polcari,

M. R. (2007). A Total Approach to Industry Sustainability. Semiconductor

International, 30(1), 108-108.

R.

Shirley, C. J. (2012). A Household Carbon Footprint Calculator for Islands:

Case study of the United States Virgin Islands. JOurnal of Ecological

Economics, 8-14.

Raja

Ariffin, R. G. (2015). Drivers and Barriers Analysis for Green Manufacturing

Practices in Malaysian SME,s: A Priliminary Finding. 12th Global Conference

on Sustainable Manufacturing, 658-663.

Ramachandra,

T. (2015). Assessment of Carbon Footprint in Different Industrial Sectors. Journal

of cleaner production, 125-132.

Rebekah

Shirley, C. J. (May 2012). A household carbon footprint calculator for islands:

Case study of the United States Virgin Islands. Journal of ecological

economics.

S

Sharma, H. G. (1995). The Objectives of Waste Management in India: A Future

Inquiry. Technological Forecasting & Social Change, 285-309.

S.

A. Shaheen, T. E. (2007). Reducing greenhouse emissions and fuel consumption –

sustainable approaches for surface transportation. IATSS Research, vol.31

no.1.

Sage,

A. (1977). Interpretive Structural Modeling: Methodology for Large-Scale

Systems. Journal of Industrial Application, 111-117.

Sangwan,

K. S. (2006). Performance Value Analysis for Justification of Green

Manufacturing Systems. Journal of Advanced Manufacturing Systems, 59-73.

Saxena,

J. (2012). The impact of indirect relationships in classification of variables:

A MICMAC.

Sharma

H.D., G. A. (1995). The objectives of waste management in India: a future

inquiry. . Technological Forecasting and Social Change, 285–309 .

Sharma,

M. (2016). Comprehensive Study on Green House Gases (GHGs) in. Kanpur:

Indian Institute of Technology, Kanpur.

Shen,

B. (2012). The Impact of Ethical Fashion on Consumer Purchase Behavior. Journal

of Cleaner Production, 16, 234-245.

Shirley,

R. (2012). A household carbon footprint calculator for islands: Case study of

the United States Virgin Islands. Journal of Ecological Economics,

111-120.

Silvia

Cosimato, O. T. (2014.). The Influence of Green Innovation in Logistics

Competitiveness and Sustainability: The DHL Case Study. 17th Toulon-Verona

International Conference (pp. 65-69). Liverpool: Liverpool John Moores

University.

Sonja

J. Vermeulen, B. M. (2012). Climate Change and Food Systems. Annual Review

of Environment and Resources, 195–222.

Sutor,

L. (2007). Green Manufacturing Comes of Age. Control Engineering, 54(11),

69-72.

T.V.

Ramachandra, S. (2012). Decentralised Carbon Footprint Analysis for Opting

Climate Change Mitigation Strategies in India. Journal of Renewable and

Sustainable Energy, 16, 5820–5833.

Tan,

X. C. (2008). A Decision-Making Framework Model of Cutting Tool Selection for

Green Manufacturing and its Application. Journal of advance manufacturing

systems, IV, 257-260.

Tan, X. C. (2012). A Decision Making

Framework Model of Cutting Fluid Selection for Green Manufacturing and a Case

Study. International Journal of Material Processing Technology, 109-123.

Technopak

Advisors. (2015). Indian Apparel Industry-A Review. Technopak Advisors.

New Delhi: Technopak Advisors Pvt. Ltd.

The

Fiber. (2011). Sustainablity Trends in India in Textile and Apparel Industry. The

Fiber, pp. 65-74.

The

Organisation for Economic Co-operation and Development (OECD). (2004).

The

Organisation for Economic Co-operation and Development (OECD). (2008).

Tikka,

P. K. (2000). Effects of educational background on students' attitudes,

activity levels, and knowledge concerning the environment. Journal of

Environmental Education, 104-116.

Timo, R. (2008). Creating fashion

without the creation of fabric waste, sustainable

fashion: Why now? A conversation about issues, practices, and possibilities.

New York: Fairchild Books, Inc.

United

Nations Environment Programme. (2015). Life

cycle management. How business uses it to decrease footprint, create

ppportunities and make value chains more sustainable. Oslow:

United Nations. Retrieved from www.unep.fr: www.unep.fr

United

Nations Industrial Development Organization. (2014). Emerging Green

Technologies for the Manufacturing Sector. Newyork: United Nations

Industrial Development Organization.

Venkatesh,

V. G. (2015). Factor influencing sucessfull implementation of green manfacturing.

International Journal of Industrial Engineering, III, 1-16.

W.R.

Teague, S. A. (2016). The role of ruminants in reducing agriculture’s carbon footprint

in North America. Journal of Soil and Water Conservation, 84-93.

Warfield,

C. &. (1994). System approaches to

management. Newyork: Sage.

Wells,

R. O. (2007). The Automobile Industry & Sustainability. Journal of

Cleaner Production, 15, 989-993.

Wendy

Tjan, R. R. (2010). A graphical representation of carbon footprint reduction

for chemical processes. Journal of Cleaner Production, 848–856.

Woolridge AC, W. G. (2006). Life

Cycle Assessment for Reuse/Recycling of Donated Waste Textiles Compared to use

of Virgin Material: An UK Energy Saving Perspective. Resources Conservation

and recycling, 46(1), 94-103.

World

Commision on enviroment and development. (1987). USA: WCED.

World

Research Institure. (2015). Report on World Climate. World Research

Institute. Zeneva: World Research Institute.

Wu,

G.-C. (2014). The Effects of GSCM Drivers and Institutional Pressures on GSCM

Practices in Taiwan’s Textile and Apparel Industry. International Journal of

Production Economics, 618-636.

WWF. (2009). Cleaner, greener

cotton: Impacts and better management practices. WWF Report.

X.

C. Tan, F. L. (2014). A decision making framework model of cutting fluid

selection for green manufacturing and a case study. Journal of material

processing technology.

Xing

Luo, J. W. (2015). Overview of current development in electrical energy storage

technologies and the application potential in power system operation. Journal

of Applied Energy , 511–536.

Yang,

Y. L. (2003). Greenness assessment of products in PLCA by DEA approach. Journal

of Material Science-A, 645-648.

Zhang, H. &. (2005). Green manufacturing process assessment by DEA method. Journal of Cleaner Production, 523-527.

|

|

©

The Author(s)

2022. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. |