H. Mary Henrietta

Department of Mathematics, Saveetha Engineering College (Autonomous), Chennai, India

K. Kalaiyarasi

UG Scholar, Department of Agriculture, Saveetha Engineering College (Autonomous), Chennai, India

A. Stanley Raj

Department of Physics, Loyola College (Autonomous), Chennai, India

*Corresponding author: mary.henriet123@gmail.com

Abstract

The coconut tree (Cocos nucifera) is one of the most extensively and widely used palm trees. The coconut palm is regarded as the "tree of life," or "Kalpavriksha." Humans have been cultivating a wide range of coconut trees around the world. This study is based on analysis of secondary data on cultivation of coconut trees and its benefits. Due to increased insect infestations and a changing habitat, the lifespan of coconut trees have been affected. Coconut product market has become the fastest expanding business due to the anti-viral compounds found in it. The coconut is used to produce oils, even the shells used for craft materials. People have been using coconut trees to make brooms and woods are being used to make furniture, construction materials for dwellings, and hardwood floors. It shows the livelihood of people around the world have been changed due to the cultivation of coconut trees. Indonesia, India and Philippines are top three countries to be economically benefitted from the plantation of coconut trees. As there is high demand of coconut based products worldwide, farmers need to be made aware about this economic value for increment in production.

Keywords: Agriculture, Coconut, Cocos nucifera, Palm, Product

DOI: https://doi.org/xx

Conflicts of interest: None

Supporting agencies: None

Received 13.02.2022; Revised 05.04.2022; Accepted 17.04.2022

Cite This Article: Henrietta, H.M., Kalaiyarasi, K., & Raj, A.S. (2022). Coconut Tree (Cocos nucifera) Products: A Review of Global Cultivation and its Benefits. Journal of Sustainability and Environmental Management, 1(2), X-X. doi: xxxxxxxx

Download full article

1. Introduction

Coconuts are diversified based on its shapes and sizes.

The most essential thing of coconut fruit is its antiviral capabilities. It

comprises of three major sections that are utilized extensively, namely,

endosperm (kernel meat), endocarp (shell), and mesocarp (coir) (Varghese and

Jacob, 2017). Both the flesh and dried form of kernel meat can be used. The

shell is utilized to design handcrafts, and coir is used to create mat rope.

According to a study conducted by Dayrit (2020), the coconut product market is the

fastest expanding business due to the anti-viral compounds found in it, which

demonstrate efficacy in the treatment of COVID-19. It also includes minerals

including Salt, Iron, Calcium, Magnesium, Phosphorus, and Selenium, as well as

Vitamin C, E, B1, B3, B5, and B6 (Ijinu, Anish, Shiju, George, &

Pushpangadan, 2011). Coconut oil benefits cardiovascular health, blood sugar

management, and cognitive performance in Alzheimer's patients. Coconut milk is

a hair conditioner as well as a component of a DIY face mask. To celebrate the

production, September 2nd has been declared as the World Coconut Day by the

members of the International Coconut Community (ICC), of which India is also

the founder member (Jayasekhar, Chandran, Thamban and Muralidharan, 2019).

According to Mandal (2011), coconut is considered as the

most beneficial plant groups known to humans. Among the beneficial palms, three

species are commercially valued, the date palm (Phoenix dactylifera), oil palm

(Elaeis guineensis), and coconut palm (Cocos nucifera). Palm trees have offered

food, water, fuel, and shelter to people in tropical and subtropical climates

for generations. As a result, the coconut palm is known as

"Kalpavriksha," or "Life Tree" (Chalbhagath & John,

2014). Oil palm and coconut palm fruits provide valuable oil, which is used in

margarine, cooking oil, soap, cosmetics, pharmaceuticals, and fuel.

Additionally, the white meat section of the coconut, copra is frequently

utilized in the confectionery and pastry industries, particularly in Sri Lanka

(De Silva, 1979). Eastern Indonesian countries refer copra as "green

gold" (Evita, 2020). Loomba (2013) has mentioned coconut having the

medicinal properties and herbal remedies. Coconut husks are used for coconut

matting and provide a considerable source of fuel. This study was conducted to

explore the numerous aspects of coconut and its beneficial effects globally. The

beneficial of nutritious intake and anti-viral agents against COVID-19

(Henrietta, 2021) has also been discussed.

2. Materials and methods

The literatures for the review were collected from Google

Scholar. Most of the studies carried in last five years have been included in

the study. The literatures were searched by using Phrases (keywords) like

“Coconut Tree”, “Benefits of Coconut”, “Products from Coconut”, “Planting

Coconut Trees” and “Coconut in India”.

3. Results and discussion

3.1. Coconut plantations

The coconut palm is a popular tree crop that produces a

variety of items for both home and commercial usage. According to Then kek hoe

(2018), the coconuts are cultivated in 93 nations with major portion occupied

by Indonesia, Philippines, and India. According to Coconut Development Boards

(CDB) figures for 2018-2019, India produced 21,384 million nuts from a 2.1

million area, with a yield of 9,815 nuts per hectare (Novarianto, 2021).

3.2. Site

selection

For coconut plantation, a site should have well-drained soil, sandy loam, or loamy texture to make it easier to remove seedlings from the nursery at planting time. The recommended pH range for a nursery is between 5.5 and 7.0, whereas seedlings tolerate a pH range of 4.5 to 8.5. Thamban (2020) proposed that the seed nuts should be planted in long, thin beds with a 40cm*30cm spacing either vertically or horizontally in 20-25cm deep trenches. Irrigation systems like sprinklers, microjet sprinklers, and hoses are ideal for coconut nurseries. The polybag nursery technique also helps to grow more strong seedlings with the improved establishment.

Only 9-12

month-old seedlings should be chosen for early germination, rapid development,

and seedling vigor. Novarianto (2021) suggested that before planting is done it

is essential to use the best planting materials to provide increased production

per unit area per unit time. In the square system, a spacing of 7.5m*7.5m to

8.0m*8.0m is commonly suggested (Subramanian, Maheswarappa, Zachariah, Surekha,

Selvamani, & Bhat, 2016). There will be 177 and 156 palms per hectare

respectively (Rani, 2020). An extra 25 palms can be planted if the triangle

technique is used. The depth of planting trenches will be determined by the

soil type.

3.3. Fertilizers

Fertilizers with

500 grams of nitrogen, 320 grams of P2O5, and 1200 grams of potassium per palm

per year are normally suggested for mature plantations (Thomas & Shantaram,

1984). Biofertilizers like Azospirillum species and phosphate soluble bacteria

produced in carriers like talc or vermicompost should be applied at a rate of

100g per palm. Rhinoceros beetle is the most well-known pest in the coconut

industry (Bedford, 2014). Prophylactic treatment of the top three-leaf axils

with either botanical cake [Neem cake, Marotti cake, or pungam cake(250g)]

admixed with an equal amount of sand or placing of 12g naphthalene balls coated

with sand can be used to manage this pest.

The palm

continues to yield for over 80 years (Narayana & Nair, 1989). Coconut can

also support a wide range of intercrops and businesses. Nihad (2020) discussed

that floriculture is a form of agriculture in which flowering plants are placed

in between the spacing of coconut trees, since the gap between the trees is

broader, providing farmers with a higher yield in addition to coconut

production to sustain their livelihood (Chikaire, Ajaero & Atoma, 2022). The

dual purpose of hydroponics was analyzed (Henrietta, 2021).

3.4. Dwarf coconuts plantations

In recent years,

the proliferation of dwarf coconut variants has grown. Copra produced by hybrid

coconuts is of a higher grade. These dwarf coconut variants have become popular

due to a scarcity of coconut climbers. Tebing Tinggi Dwarf (TTD), Bali Yellow

Dwarf (BYD), Nias Yellow Dwarf (NYD), Jombang Green Dwarf (JGD), Nias Green

Dwarf (NGD), Waingapu Red Dwarf (WRD), Raja Brown Dwarf (RBD), Sagerat Orange

Dwarf (SOD), Salak Green Dwarf (SGD), and Hybrid Coconut (KHINA 1) are the

noteworthy dwarf coconut kinds (Sopade, Samosir, Rival, & Adkins, 2010;

Novarianto, Mashud, Samosir, & Adkins, 2014; Welewanni & Bandupriya,

2017; Novarianto, Tulalo, & Mawardi,

2021). In Brazil, dwarf variants are commonly employed for economic purposes.

When compared to the red type, the green variety is the most marketable owing

to its flavor (Joao, 2017), Marcelo Coconut is derived from these dwarf

variants, which are commercially farmed. Dissanayaka (2012) proposed that these

types of varieties generate huge, high-quality nuts in three years after

planting.

3.5. Coconut components

Coconut water,

the white fleshy section (known as copra when dried), shells, husks, leaves,

and flowers are the most important parts of the coconut. Until the coconut is

opened, the delicate coconut water is utilized as a beverage. Coconut water is

also used to make the gelatinous delicacy ''Nata de Coco," which has

gained popularity in Japan (Gayathry, 2015). The white fleshy section of an

immature coconut has a flavor and consistency similar to custard, and it may be

eaten or scraped and pressed through cloth to produce a 'cream' or 'milk' that

can be used on a variety of meals. In China and Vietnam, half-dried coconut

shells are utilized as the bodies of musical instruments. Ringworm is treated

using a mixture of ash from the mature shell of the fruit and lime. Pieces of

coconut shell cut into coin-like spheres were used as money in the South

Pacific. Coconut shells are now utilized as craft materials as well. The

fibrous coating on the thick mesocarp (middle layer) of the coconut fruit is

referred to as coconut husks. The coconut husk is made up of 75% fibre and 25%

fine particles. It's also known as 'coir pith.' Coco husk chips, coco peat,

coir fibre, and coco crush are all made from the husks.

Coco peat has

long been utilized as a fertilizer in indigenous peoples' gardens (Lu, Wang,

Liu, He, Wu, Li, & Tang, 2020). Coco peat is also utilized economically to

conserve wetlands as a renewable resource. Coir pith may be used to make good

manure by putting it in the cow shed and then removing it every day and dumping

it in the compost pit. It is also utilized in horticulture and has taken the

place of peat moss. Coconut leaves are used for thatching. These leaves are

used to construct fences and roofs for tiny homes. In the Philippines, rice is

wrapped in coconut palm leaves for cooking and storage, a process known as

Puso. Coconut blossoms may be eaten. In ancient times, they were combined with

curd and consumed by diabetics, as well as used for a variety of medical

purposes. In Kiribati, an island country in the central tropical Pacific Ocean,

cutting a coconut blossom cluster yields a delicious juice that is consumed for

breakfast and supper when it is fresh and not fermented. Subash (2014)

indicated that through ancient times, coconut blossoms have been widely

employed in medicine.

3.6. Coconut products

Coconut goods

are divided into kernels, inflorescence, shell, water, and handy food items by

the Coconut Development Board. Virgin coconut oil, desiccated coconut, coconut

milk, coconut skimmed milk, spray-dried coconut milk powder, coconut cream,

coconut chips, coconut oil, and copra are examples of kernel-based coconut

goods (Appaiah, Sunil, Kumar, & Krishna, 2015).

Virgin coconut oil

The white fleshy

section of the coconut is broken down and pressed in a screw press to extract

coconut milk, which is then filtered, and the cream is separated using

centrifugation. A method known as phase inversion is used to extract the Virgin

Coconut Oil (VCO) from the cream. The resulting oil is crystal clear,

nutrient-dense, and has a longer shelf life. Wet processing without heat

treatment is used to extract virgin coconut oil from fresh, mature coconuts.

Virgin coconut oil is colorless and smells strongly of coconut. This oil

contains lauric fatty acid, which has been shown to have antiviral and

antibacterial properties. Due to the presence of natural antioxidants in

coconut oil, high-grade VCO has a long shelf life. Navin (2019) discussed that

coconut oil is a tropical climate product which is in high demand in the

cosmetics sector and in worldwide cuisine.

Desiccated coconut

Desiccated

coconut meat is grated and shredded dehydrated coconut (DC) meat (Jayasekara

& Gunathilake, 2007). It is widely utilized in India, mostly in the

confectionery and other food sectors. It's also used as a replacement for

shredded coconut in a variety of dishes.

Coconut milk

Coconut milk is

an emulsion of two liquids made from the flesh of the coconut. The coconut cream

and coconut water are sterilized coconut flesh that is grind into paste using a

hammer mill, then passed through a screw press and vibrating screens to make

coconut milk on an industrial scale (Sudheer, 2018). To dilute coconut milk, it

is cleansed and blended with coconut water and pure water. After that, 10-12%

sugar is added and a 2% stabilizer, emulsifier, and taste, then the blend is

sterilized and packed in bottles and sent for sales.

Coconut skimmed milk

After the cream

has been separated in a cream separator, coconut skims milk is a solution of

the soluble components of coconut. Skimmed milk is a great source of protein

that is used to make a variety of beneficial foods (Naik, Raghavendra, &

Raghavarao, 2012). With the addition of sodium hydroxide, freshly obtained

coconut milk from the kernel is filtered through a 120-mesh vibrating screen

and the pH of the filtered milk is increased from 6.3 to 7.0. The milk is then

pasteurized for one hour at 60 degrees Celsius before being centrifuged in a

cream separator to extract the aqueous phase, which contains the protein-rich

skim milk. The skimmed milk is also used to make items like spray-dried powder,

coconut honey, coconut jam, and sweetened skim milk (Muralidharan, 2011).

Spray dried coconut milk powder

The

manufacturing of whole coconut milk powder entails several activities,

including size reduction, milk extraction, emulsion stabilization,

homogenization, and spray drying (Seow & Gwee, 1997). Spray drying is a

technique that has been developed to help stabilize coconut milk. The white

endosperm is removed from the shell and driven out via a rotary wedge cutter

with a filter plate (3 mm hole). In a screw press, the wet coconut grating is

then pressed to obtain coconut milk. For over 30 minutes, the coconut milk is

homogenized in two stages of high and low pressure. The milk is then

manufactured by adding various additives and chemicals. The coconut milk is

then homogenized again after being pasteurized at 60-70 degrees Celsius for 5

minutes. Finally, the milk is spray-dried at a feed flow rate of 120 ml/minute

at a temperature of 100-150 degrees Celsius and packaging is done.

Coconut cream

Coconut milk is

made from partly defatted coconut cream. Coconut cream/milk is used as a

component of processed foods and as an ingredient in domestic cooking. Coconut

milk is also known as coconut cream, which is used as a mixer in alcoholic

beverages. According to Novarianto (2021), in ice cream industry, coconut milk

is utilized as a dairy milk alternative. Because dairy milk has a larger fat

content than coconut milk which reduce the fat content of coconut milk and can

be utilized to make a variety of goods.

Coconut chips

Coconut chips

are a snack item that is ready to consume (Manikantan, 2015). Coconut chips are

dehydrated mature coconut kernel slices that have been dipped in an osmotic

medium such as sugar syrup. Coconut chips do not alter nutritionally or

chemically after six months. To reduce chip breakage during shipping, nitrogen

flushing is done in pouches (Sudheer, 2018).

Coconut oil

Coconut oil is

an edible oil that has been eaten for thousands of years in tropical areas

(Boateng, Ansong, Owusu, & Steiner-Asiedu, 2016). Crushing of dried

coconuts (copra) for oil recovery is done with rotary and expeller machines

(Figure 1) used in the outskirts of Tanjore, Tamil Nadu. The oil content from

copra is 60-65%. There are two major ways of extracting coconut oil; dry and

moist (Marina, Man & Amin, 2009). The coconut is dried in the dry

extraction method, but the wet extraction method does not include any drying.

The goal of dry extraction is to remove moisture from coconut fruit while

minimizing microbial contamination. Heating, fermentation, cream centrifuge, pH

adjustment, and chilling are all used in the wet extraction process. Large

enterprises frequently carry out oil extraction by employing dry extraction

with copra processing. As a result, dry extraction requires more oil

refinement. A centrifuge may be used to do mechanical extraction. Apart from

this, enzyme extraction and solvent extraction are the two more ways of

extracting oil (Subroto, 2020).

Copra

There are two

types of copra produced in India: milling and edible copra (Ramakumar, 2001).

The edible coconut is consumed as dry fruit, while the ground copra is used to

extract oil. When compared to other oilseeds, copra has the greatest amount of

oil. Eastern Indonesia's economy has been reliant on copra for over eight

decades (green gold). The need for cooking oil in European nations increased in

the 1880s, prompting the discovery of copra oil as a new cooking tool. Copra is

also a component in the making of butter. The Copra is also utilized in the

production of soap (Evita, 2020).

3.7. Coconut water-based products

It is observed

that numerous products result from coconut water; tender coconut water,

Vinegar, Coconut squash, and Nata-de-coco.

Tender coconut water

Coconut water is

the liquid endosperm of a delicate coconut nine months after pollination when

the solid endosperm, or white flesh, appears. The most healthy and healthful

beverage is tender coconut water. Tender coconuts are excellent for preserving

coconut water. However, according to Sudheer (2018), the nuts cannot be kept at

room temperature for more than six days.

Vinegar

Coconut vinegar

is a natural product made from the fermentation of coconuts, with no additional

preservatives or additives (Othaman, Sharifudin, Mansor, Kahar & Long,

2014). Coconut water or fermented coconut sap is used to make this vinegar.

It's made with Saccharomyces cerevisiae (yeast) and Acetobacter aceti

(bacteria) to help with ethanol and acetic acid fermentation. (Sudheer, 2018)

discussed that coconut vinegar is made by the alcoholic fermentation of coconut

water with the addition of 10-12% sugar and it entails fermenting sugar into

ethanol and then oxidizing the ethanol to make vinegar.

Coconut squash

Coconut squash

is a healthful soft drink made with coconut water, sugar, and natural

preservatives like lemon and ginger (Chinnamma, Bhasker, Binitha Hari,

Sreekumar, & Madhav, 2019). It has a high vitamin and mineral content while

being low in calories. This product has a three-month life at room temperature.

It's a relatively new product that's gaining traction in Asia and the Pacific.

Nata de coco

Acetobacter aceti subspecies xylinium, a cellulose-forming

bacterium, produces nata-de-coco, a gelatinous substance made from matured

coconut water. The culture solution is made by combining coconut water, sugar,

and acetic acid in a predetermined proportion, then inoculating it with

Acetobacter, Xylinium via a culture liquid. It is placed in glass jars with

thin linen covering and left undisturbed for 2-3 weeks. During this time, a

white jelly-like substance develops on top of the culture medium and floats. It

is picked, chopped into pieces, cleaned in pure water to eliminate all acids,

and then soaked in flavored sugar syrup for 12 hours before being packaged in

glass bottles (Muralidharan, 2011).

3.8. Coconut based products

There are two

major categories of foods that are extracted from coconut, coconut

inflorescence-based foods, and coconut convenience foods.

Coconut inflorescence-based foods

It is seen that

neera, coconut jaggery, and coconut flower syrup are all coconut

inflorescence-based foods.

Neera: Neera is a fresh form of vascular sap taken from immature

unopened coconut inflorescence (Chinnamma, Bhasker, Binitha Hari, Sreekumar,

& Madhav, 2019). To preserve the product, it is tapped from coconut

inflorescence, filtered, pasteurized, and bio preservatives are added. Neera

can be stored in cans for up to two months at room temperature. Tetra packs or

glass bottles are also available.

Jaggery: Jaggery is also known as palm sugar. Toddy is the sap from the

young inflorescence. Palm sugar or coconut jaggery is made from unfermented

toddy that has been carefully boiled. By adding a few drops of coconut oil or

little coconut gratings, scummy contaminants are eliminated and foaming is

avoided. Before boiling, the juice is filtered through sand filters to

eliminate contaminants, and a tiny amount of alum is added to induce lime and

magnesium precipitation, which provides the jaggery a better color and make it

tougher for a longer period of time (Muralidharan, 2011).

Coconut Flower Syrup: This is a mineral-rich substance that is

comparable to jaggery. It has a high potassium concentration and a low sodium

content. It's made from fresh neera that's been condensed into syrup. The syrup

contains 50% sucrose and is beneficial to diabetic individuals.

Coconut convenience foods

Coconut cookies,

coconut candy, coconut chocolate, and coconut burfi are examples of coconut

convenience foods. Coconut biscuits are made using coconut powder and Maida and

may be made in a variety of flavors by adding butter, ginger, chocolate, and

other ingredients. It has a three-month life at room temperature and is both

tasty and healthful, with less calories. Coconut candy is made by combining

shredded coconut with coconut milk. It is mostly produced in Asian and Pacific

nations and has a high fibre content. The coconut chocolate has

chocolate-coated confectionary treat made from coconut gratings, sugar, and

milk butter. Cashew, almond, and other dry fruits can be added to make it even

more delectable. Under refrigerated circumstances, this product has a three-month

life (Shameena, 2020). North America, Europe, Australia, the Middle East, and

China all have a high demand for it. Similarly, the coconut burfi is made by

toasting coconut gratings and the product's preparation technique is

standardized (Thamban, 2020). The coconut gratings are roasted, then fat is

added at a rate of 3% and sugar at a rate of 10%.

3.9. Components of a coconut shell-based

product

Coconut shell

powder, coconut shell charcoal, and activated carbon are the shell-based

products from coconuts.

Powder of coconut shells

Coconut shell

powder is widely used in the plywood and laminated board industries, as well as

a phenolic extruder and a filler in synthetic resin glues, mosquito coils, and

incense sticks. It's also a good alternative for bark powder, furfural, and

peanut shell powder because of its consistency in quality and chemical

composition, as well as its superior characteristics. Sri Lanka, Philippines,

and Indonesia are the main exporting countries of coconut shell powder (Muralidharan,

2011).

Coconut shell charcoal

Coconut shell

charcoal is made by burning fully grown nut shells in a little amount of air,

just enough to carbonize. Shell is carbonized in mud pits, brick kilns, and

metallic kilns to produce shell charcoal. Fully dried, clean adult shells are

utilized to make top-grade charcoal. It is utilized as a raw material for the

production of activated carbon because of its inherent value.

Activated carbon

To make

activated carbon, the coconut shell is first transformed to shell charcoal

through a carbonization process that takes place in mud pits, brick kilns, and

metal portable kilns. The coconut shell charcoal is activated in a rotating

kiln by reacting with steam at 900-1100 degrees Celsius in a controlled

environment. Three tons of coconut shell charcoal may provide up to 1 ton of

activated carbon on average (Dhamodaran & Babu, 2011).

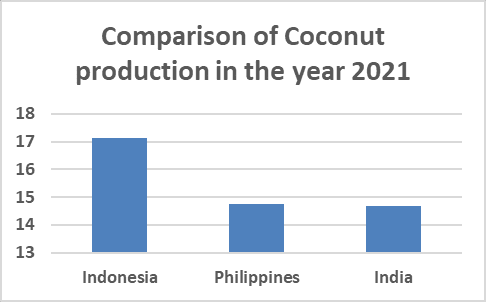

Figure 2: World-wide coconut productions

(statista.com)

Figure 3: Comparing coconut production among three countries in the year 2021.

4. Conclusion

The coconut tree

has a wide range of applications with huge influence on the lives of people all

around the world. It provides medical benefits, food, and a major source of

income for the people. Indonesia, India and Philippines are top three countries

to be economically benefitted from the plantation of coconut trees. As there is

high demand of coconut-based products worldwide, farmers need to be made aware

about this economic value for increment in production.

Acknowledgements

The authors are

thankful to the management of Saveetha Engineering College for providing the

opportunity to undergo this study.

References

Bedford, G. O. (2014).

Advances in the control of rhinoceros beetle, Oryctes rhinoceros in oil palm. Journal of Oil Palm Research, 26(3),

183-194.

Boateng, L., Ansong, R.,

Owusu, W., & Steiner-Asiedu, M. (2016). Coconut oil and palm oil’s role in

nutrition, health and national development: A review. Ghana Medical Journal, 50(3), 189-196.

Chalbhagath, A., & John,

J. P. (2014). Fungicidal bioassay on foliar fungi Associated with yellowing

disease of coconut. Pesticide Research

Journal, 26(1), 90-93.

Chikaire, J.U., Ajaero,

J.O., & Atoma, C. N. (2022). Socio-economic Effects of Covid-19 pandemic on

rural farm families’ well-being and food systems in Imo State, Nigeria. Journal of Sustainability and Environmental

Management, 1(1), 18-21.

Chinnamma, M., Bhasker, S.,

Binitha Hari, M., Sreekumar, D., & Madhav, H. (2019). Coconut neera—a vital

health beverage from coconut palms: harvesting, processing and quality

analysis. Beverages, 5(1), 22.

Dhamodaran, T. K., &

Babu, S. (2011). Potential of community level utilization of coconut shell and

stem wood for charcoal and activated carbon in Kerala. Journal of the Indian Academy of Wood Science, 8(2), 89-96.

D’Silva, A. Passos, E.M.

Fontes, H.R, et al. (2019). Advances in coconut propagation. Revista Brasileira dde Fruticultura,

41(2), 1-14.

Dissanayaka, C. Perera, C.

Jayathilake, R.S.S, et al. (2012). Development of new coconut hybrids for yield

improvement utilizing novel local dwarf coconut variety, Srilanka brown dwarf. Conference: Proceedings of the 4th Plantation

Crop Research Symposium, 1-24.

Dayrit, F.M. Mary, T.N.

(2020). The Potential of coconut oil and its derivatives as effective and safe

antiviral agents against the novel coronavirus. Indian Coconut Journal, 62, 21-23.

De Silva, H. W. S. (1979). The coconut industry in Sri Lanka: An

analysis of government intervention measures.

Evita, A.L. Mappangara, S.

Akhmar, A.M. (2020). Agribusiness and cultivation of coconut in the Netherlands

at the end of the colonial era. IOP

Conference Series: Earth and Environmental Science, 575(012108), 1-8.

Gayathry, G. (2015).

Production of nata de coco-a natural dietary fibre product from mature coconut

water using Gluconacetobacter xylinum (sju-1). International Journal of Food and Fermentation Technology, 5(2),

231-235.

Henrietta, H.M., Mohanraj,

M., (2021). Implementation of hydroponics as a twin support for electric power.

Annals of Romanian S.C.B., 25(2),

1002-1007.

Henrietta, H.M., Raj, A.S.,

Megavathi, M., Kavinil, V., Giridharan, B., (2021). An investigation on

dietetics and nutritional interests using quantitative analysis in the existing

prevalent conditions of COVID-19. Journal

of Human Health Research, 1(3), 15-23.

Ijinu, T. P., Anish, N.,

Shiju, H., George, V., & Pushpangadan, P. (2011). Home gardens for nutritional and primary health security of rural poor

of South Kerala.

Jayasekhar S., Chandran,

K.P., Thamban, C., and Muralidharan, K. (2019). Coconut sector in India

experiencing a new regime of trade and policy environment: A critical analysis.

Journal of Plantation Crops, 47(1), 48-54.

Jayasekara, C., &

Gunathilake, K. D. P. P. (2007). Processing technologies for virgin coconut oil

and coconut based Confectionaries and beverages. Proceedings of International Cococnut Summit, 7-11.

Joao, M.S. Talamini, V.

Ramos, S.R.R, et al. (2017). Evaluation of dwarf coconut (Cocos nucifera L.)

germplasm to the damage intensity caused by foliar disease. Australian Journal of Crop Science,

11(10), 1374-1380.

Loomba, S. Jothi,V. (2013).

Cocos nucifera: Its properties and contributions to dentistry. International Journal of Scientific Study,

1(3),138-140.

Lu, B., Wang, X., Liu, N.,

He, K., Wu, K., Li, H., & Tang, X. (2020). Feasibility of NIR spectroscopy

detection of moisture content in coco-peat substrate based on the optimization

characteristic variables. Spectrochimica

Acta Part A: Molecular and Biomolecular Spectroscopy, 239, 118455.

Mandal, M.D. Mandal, S.

(2011). Coconut (Cocos nucifera L.: Aracaceae): In health promotion and disease

prevention. Asian Pacific Journal of

Tropical Medicine, 4(3), 241-247.

Manikantan, M. R. (2015). Coconut chips: A healthy non-fried snack

food.

Marina, A. M., Man, Y. C.,

& Amin, I. (2009). Virgin coconut oil: emerging functional food oil. Trends in Food Science & Technology,

20(10), 481-487.

Muralidharan, K. Jayashree,

A. (2011). Value addition, product

diversification and by-product utilization in coconut.

Naik, A., Raghavendra, S.

N., & Raghavarao, K. S. M. S. (2012). Production of coconut protein powder

from coconut wet processing waste and its characterization. Applied biochemistry and biotechnology,

167(5), 1290-1302.

Narayana, D., & Nair,

K. N. (1989). Trends in area, production and productivity of coconuts in

Kerala. Indian Journal of Agricultural

Economics, 44(902-2018-2692), 159-167.

Navin, K.R. (2019). New

technologies for value added products from coconut residues. Materials Research Forum, 11, 295-301.

Nihad, K. Haris, A.

Kalavathi, S. (2020). Scope of floriculture in coconut garden. Indian Coconut Journal, 5-8.

Novarianto, H., Tulalo, M.

A., & Mawardi, S. (2021). Preliminary investigation of the potential of

coconut sugar production using dwarf varieties. Cord, 37, 23-32.

Novarianto, H., Mashud, N.,

Samosir, Y., & Adkins, S. W. (2014). Embryo maturity plays an important

role for the successful cryopreservation of coconut (Cocos nucifera). In Vitro Cellular & Developmental

Biology-Plant, 50(6), 688-695.

Novarianto, H. Tulalo, M.A.

Mawardi, S. (2021). Coconut sugar production of dwarf coconut varieties. IOP Conference Series: Earth and

Environmental Science, 800(012024), 1-9.

Othaman, M. A., Sharifudin,

S. A., Mansor, A. Z. L. I. N. A., Kahar, A. A., & Long, K. A. M. A. R. I.

A. H. (2014). Coconut water vinegar: new alternative with improved processing

technique. Journal of Engineering Science

and Technology, 9(3), 293-302.

Ramakumar, R. (2001). Costs

and margins in coconut marketing: some evidence from Kerala. Indian Journal of Agricultural Economics,

56(4), 668-682.

Rani, S. Sudhalakshmi, C.

Maheshwarappa, H.P. (2020). Coconut Nursery Establishment Techniques. Indian Coconut Journal, 3-37.

Richard Branton, Jennet

Blake (1983). A lovely clone of coconuts, New

Scientist (Magazine), 554-604.

Seow, C. C., & Gwee, C.

N. (1997). Coconut milk: chemistry and technology. International Journal of Food Science & Technology, 32(3),

189-201.

Shameena,B.P.P. Manikantan,

M.R. Pandiselvam, R, et al. (2020). Coconut in Dairy Industry. Indian Coconut Journal, 3-37.

Shareefa, M. Sreelelshmy,

J.S. Thomas, R.J, et al. (2020). Propagation Techniques in Coconut. Indian Coconut Journal, 63(8), 5-40.

Sopade, P. A., Samosir, Y.

M., Rival, A., & Adkins, S. W. (2010). Dehydration improves

cryopreservation of coconut (Cocos nucifera L.). Cryobiology, 61(3), 289-296.

Subash Chander Ahuja. S,

Ahuja. U, Ahuja. (2014). History, uses and folklore. Asian Agri-History, 18(3), 221-248

Subramanian, P.,

Maheswarappa, H. P., Zachariah, T. J., Surekha, R., Selvamani, V., & Bhat,

R. (2016). Performance of black pepper in

coconut based high density multi-species cropping system under different

nutrient managements.

Subroto, S. Pangawikan,

A.D. Yarlina, V.P, et al. (2020). The extraction, purification and the recent

applications of coconut oil in food products – A review. International Journal on Emerging Technologies, 11(5), 234-240.

Sudheer, K.P. Claudia, K.L.

Sankalpa, K.B, et al. (2018). Prospects in value addition of coconut, Technical Bulletin No: CE-PHT/2018/22.

Thamban, C. Subramanian, P.

(2020). Cultivation practices for coconut – June. Indian Coconut Journal, 3-37.

Then kek hoe. (2018). The

current scenario and development of the coconut industry. The planter Kuala Lumpur, 94(1108), 413-426.

Thomas, G. V., &

Shantaram, M. V. (1984). In situ cultivation and incorporation of green manure

legumes in coconut basins. Plant and

Soil, 80(3), 373-380.

Varghese, A., & Jacob,

J. (2017). A study of physical and mechanical properties of the Indian coconut

for efficient dehusking. Journal of

Natural Fibers, 14(3), 390-399.

Welewanni, I., & Bandupriya, D. (2017). Coconut cryopreservation: present status and future prospects. Cord, 33(1), 21-21.

|

|

©

The Author(s)

2022. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. |