Khalefa A. Faneer*

Department of Environment Engineering, Higher Institute of Science and Technology, Bent Baya, Wadi AL-Ajal, Libya

Ebrahim Mahmoudi

Department of Chemical & Process Engineering, Faculty of Engineering and Built Environment, Universiti Kebangsaan Malaysia, UKM, Bangi, Malaysia

Muneer Ba‑Abbad

Department of Chemical Engineering, Faculty of Engineering and Petroleum, Hadhramout University of Science &Technology, Mukalla, Hadhramout, Yemen

Rosiah Rohani

Department of Chemical & Process Engineering, Faculty of Engineering and Built Environment, Universiti Kebangsaan Malaysia, UKM, Bangi, Malaysia

*Corresponding author: k.fneer@niclibya.com

Abstract

The urgent concern of water shortage have promoted to the development of different sustainable technologies with the rapid evolution of nanotechnologies. Graphene oxide (GO) is a water-soluble material that can be constructed into a number of structures such as membranes, and has many applications in environmental sectors. Furthermore enhancing membrane characteristics to improve water flux performance and mitigate fouling is crucial issue for membrane separation technology. GO serves as nanofiller to overcome fouling during filtration as well as water flux improvement. This work aimed to develop PES membranes by phase inversion method and the fabricated membranes subjected to series analysis of FESEM, hydrophilicity and water flux. The results showed that the GO improved the contact angle of the pure PES membrane and the water flux increased from 13 to 16 L/m2.h. Therefore, the PES-GO membrane proved its capability to be used for various applications to reduce membrane fouling.

Keywords: Fouling, Graphene oxide, Membrane, Nanocomposite, PES, Water

DOI: https://doi.org/x

Received 28.02.2022; Revised 02.05.2022; Accepted 07.05.2022

Cite This Article: Faneer, K.A., Mahmoudi, E., Ba‑Abbad, M., & Rohani, R. (2022). Graphene Oxide Nanocomposite for Sustainable Pure Water by PES Membrane. Journal of Sustainability and Environmental Management, 1(2), x-x. doi: xxxxxxxx

Download full article

1. Introduction

Water resource sustainability is essential for the

long-term evolution of modern society and economy. More strain on water

resources deficit has been developed as a result of industrialization and human

activities, which has accompanied the rapid expansion of the economy and

society (Al Aani, Mustafa, & Hilal, 2020). Due to high growing in industry,

the oily wastewater has increased dramatically, thus the surrounding

environment such as drinking water as well as ground water and sea water being

impacted significantly. As a result, the harm to the ecosystem as a whole may

increase. Membranes, electrochemical, biological, UV irradiation, hybrid

technologies, and destabilization of emulsions by adding minerals are only a

few of the approaches that have been tested so far to remove oil from water. A

variety of membranes, including those generated through interfacial

polymerization, nanoparticle incorporation, and surface grafting, have been

emphasized. (Bolto, Zhang, Wu, & Xie, 2020). Membrane technology, particularly

Ultrafiltration (UF) membranes, has advanced significantly since the 1970s as a

safe, clean, cost-effective, and effective separation method for a variety of

components and contaminants in water and wastewater (Ismail, Khulbe, &

Matsuura, 2015). Due to uniformity in the separation process, no chemicals

added in or during the filtration process, high separation performance

efficiency, ease of operation, and small footprint, polymeric membranes play a

large role in separating oil from oil-water emulsions. The membrane acts as a

barrier, preventing oil droplets from flowing through but allowing water

molecules with smaller hydrodynamic particle sizes to pass through. In general,

the membrane's surface parameters (pore size, porosity, surface wettability, and

surface roughness) have a big impact on both permeate flux and rejection (Teow

& Solihuddin, 2020).

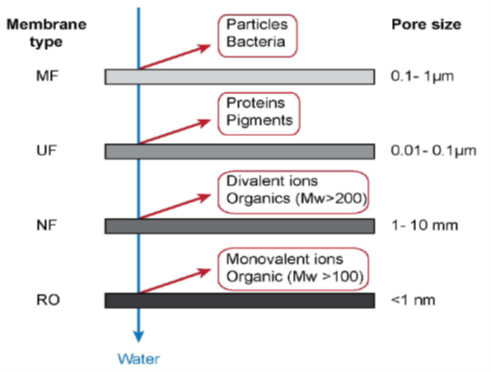

Microfiltration (MF), ultrafiltration (UF),

nanofiltration (NF), reverse osmosis (RO), forward osmosis (FO), and membrane

distillation (MD) are examples of novel water purification and reclamation

techniques (Zhang et al., 2016). These membranes are classified based on pore

size measurements (Figure 1), furthermore, each filtration process works in the

specific range of operating pressure (Kumar et al., 2013). Among these

membranes, MF and UF are the major filtration processes used for oil removal.

Furthermore, hydrophilic surfaces will repulse oil droplets from the membrane

and facilitate the passage of water (Zhu, Loo, & Bai, 2013). Membrane

fouling has been a barrier in membrane water treatment technology since its

inception, reducing water permeation flux, degrading product water quality, and

increasing energy usage (Shannon et al., 2010). Membrane fouling can result in

a temporary or permanent decrease in flux as a result of pore clogging, cake

formation, organic and inorganic precipitation, and biological fouling. Because

of direct interaction with various types of foulants in the raw water,

practically all membrane processes suffer from fouling difficulties when used

for long-term water purification (Zhang et al., 2016).

In order to deal with membrane fouling, various routs have been attempted, such as: surface modification by incorporating antifouling materials. In recent years, the Graphene (G) and Graphene Oxide (GO) have become one of the most important commercial nano-sheets in the world. GO is the derivative of the graphene and it has been extensively explored for the adsorption of various pollutants (Baig, Sajid, & Saleh, 2019). Researchers concern attracted to graphene (G) and graphene oxide (GO) due to many reports on their mechanical and chemical properties when incorporated with the membranes ( Yeh, Cihlář, Chang, Cheng, & Teng, 2013; Mahmoudi, Ng, Ba-Abbad, & Mohammad, 2015). The GO materials have a great potential for absorbing organic molecules in aqueous solutions. (G. P. Rao, Lu, & Su, 2007), the GO membrane is extremely effective in removing organic pollutants and dyes from solution. Adsorption, flotation, and biological treatment are some of the technologies used in industry to treat produced water for disposal or reuse in other processes. These technologies, on the other hand, are ineffective for de-oiling water with droplet sizes smaller than 10 μm. Hybrid techniques have also been tried to break down the oil droplets, but these are energy-intensive and environmentally damaging. Membrane technology, on the other hand, has been recognized as a viable approach for oil emulsion separation that uses less energy and has a reduced environmental impact. (Alammar, Park, Williams, Derby, & Szekely, 2020). Rao et al. (2014) reported efficient removal of 4-chlorophene, 2,4-dichlorophene, and 2,4,6-trichlorophene by ZrO2 graphene composite compared pure membranes. Chung, Y.T., et al. stated that the PSf composite membrane with Zn-GO exhibits excellent antifouling and antibacterial properties (Chung et al., 2017). Furthermore, the advantages of using GO as a nanoplates with nanoparticles is to offer a good and homogenous distribution of the nanoparticles across the membrane matrix (Mahmoudi et al., 2015). Various kinds of polymer including Polyethersulfone (PES), Polysulfone (PSf) and Polyamide (PA) are frequently utilized in membrane fabrication as a base polymer ( Hamid et al., 2011; Nghiem, 2013; Faneer, Rohani, & Mohammad, 2016; Fujioka). Because of its great thermal stability and mechanical strength, PES is a promising polymer for membrane modification. However, lack of hydrophilicity causes fouling and low permeability considered a main failure of the PES membrane. Thus, recently some researches on incorporation of GO with PES membranes were applied to overcome these obstacles of using a PES as a base polymer (Wu, Tang, & Wu, 2014b; Mahmoudi et al., 2015). Therefore, this work aimed to fabricate PES and PES/GO 1 % membranes to improve membrane performance with enhanced water flux rate and better hydrophilicity which minimize the operation cost.

Figure 1:

Membrane processes classification according to the pore size

2. Materials and methods

2.1. Materials

Polyethersulfone (PES) granules were used from Goodfellow

Cambridge Ltd., England. The solvent 1-methyl-2-pyrrolidinone (NMP, 99.5%

purity) was of analytical grade and purchased from Merck Co., Germany.

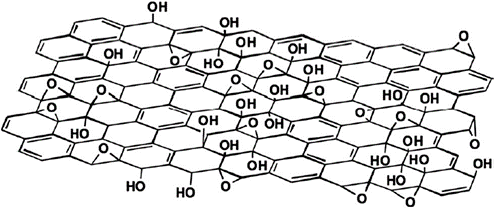

Ultrapure water was used as non-solvent. GO nano-sheets was synthesized in the

lab (refer to (Mahmoudi et al., 2015; Ba-Abbad, Mohammad, Mahmoudi, Faneer,

& Benamor, 2016). The chemical structure of graphene oxide is illustrated

in Figure 2.

2.2. Synthesis

of the Membranes

Nanocomposite membranes were created utilizing phase

inversion induced by immersion precipitation. For membrane fabrication, a

suitable amounts of PES (18 wt. %) were dissolved in solvent NMP (82 wt. %) with

mechanical stirring speed at 250 rpm for 6 h. Afterward, the prepared GO

nanoparticles with 1 % concentration were added into the mentioned polymeric

solutions. Mixing was followed by sonication for 30 min for breaking up

aggregates between nanoparticles. To thoroughly remove the air bubbles, the

produced solutions were left at room temperature for around 24 hours without

stirring. Then, using a film applicator, they were cast onto clean glass plates

with a consistent thickness of 200 m. Next, immerse the glass plate

horizontally in distilled water having an ambient temperature. The membranes

were maintained in fresh distilled water for 24 hours after primary phase

separation and solidification to guarantee complete solvent exchange. The

membranes could then be used. The polymeric solution compositions are presented

in Table 1.

|

Main Polymer |

Solvent |

GO amount |

Remarks |

|

PES

18 % |

NMP

82 % |

None |

|

|

PES

18 % |

NMP

82 % |

1

% |

Sonication

for 30 min |

Membrane

performance

The fabricated membranes performance was evaluated

through a dead-end stirred cell setup. The experiment was performed at fixed

pressure (4 bar). The pure water flux was calculated according to the following

equation

where Jw is the water flux (L/m2.h), V is the

permeate volume (L), A is the membrane effective area (m2), t is the

permeation time (h).

Contact

angle measurement

Using a Rame-Hart model 200 standard contact angle

goniometer with DROPimage Standard Software, the hydrophilicity of the

manufactured membranes was determined with an accuracy of 60.100.

The membranes were dried for 48 h and the medium used to measure the contact

angle was deionized water and air at ambient temperature (25 – 28 0C).

Field

emission scanning electron microscopy (FESEM)

FESEM Merlin Compact (Zeiss, Germany) was used to examine

the cross sectional structures of the fabricated membranes. Prior the FESEM

analysis, membrane samples were fractured into an appropriate size by using

Nitrogen liquid and mounted on the sample holder.

3. Results and discussion

3.1. Membrane

performance of water flux and hydrophilicity

Changes in the water flux of the membranes as a result of

blending of hydrophilic materials (GO) were investigated via the pure water

flux measurements. The GO-PES membrane shows higher water flux at 16 L/m2.h

comparing to PES membrane at 13 L/m2.h as presented in Figure 3.

To evaluate the hydrophilicity of blank and blended PES

membranes, the contact angle analysis was used. Figure 3 exhibits the results

of contact angle measurements for 1 wt.% of GO. The contact angle of blank PES

membrane decreases from 80.0º to 64.7º by blending with 1 wt.% GO. The

significant number of oxygenated groups of the GO nanosheets scattered in the

polymer matrix can be attributed to the improved hydrophilicity of GO/PES

membranes compared to blank PES. (Safarpour, Khataee, & Vatanpour, 2015),

this may have a positive impact on the blended membranes' pure water flux.

It clearly observed that the improvement in membrane hydrophilicity has the same trend of water flux increase. Water permeability is increased by enhancing the membrane's hydrophilicity, which attracts water molecules inside the membrane matrix and facilitates their penetration across the membrane. As a result of the high water flux, low contact angle, and good hydrophilic character of the produced GO-PES membrane, the results demonstrated that it performed well. Therefore, adding GO to PES membrane enhancing the membrane antifouling properties.

3.2. FESEM

The cross-sectional FESEM images of the prepared mixed

matrix membranes are presented in Figure 4.

The PES and GO-PES membranes have an asymmetric structure with a finger-like porous sub-layer and a skin top-layer. The addition of GO to the polymer matrix modified the membranes' finger-like shape slightly. Also, with the addition of GO to the membrane structure, the pore size of the membrane structure grows greater. The same finding was established by (Wu, Tang, & Wu, 2014a; Shanmugam, 2022) where the membrane pores became bigger as SiO2/GO added to membrane matrix.

a b

Figure 4: FESEM cross sectional images of (a) PES and (b) GO-PES membranes

4. Conclusion

GO nanocomposites are promising for high membrane

performance to obtain sustainable clean water. In addition, from the aspects of

nature of GO hydrophilicity, the membrane morphology and antifouling properties

provided efficient outcomes. As a result, it could be concluded that

incorporating GO NPs into PES membranes was an advanced method for developing

superior membranes with increased hydrophilicity and fouling control that were

ideal for a variety of purification and environmental applications.

References

Alammar, A., Park, S.-H.,

Williams, C. J., Derby, B., & Szekely, G. (2020). Oil-in-water separation

with graphene-based nanocomposite membranes for produced water treatment. Journal of Membrane Science, 603,

118007.

Ba-Abbad, M. M., Mohammad,

A. W., Mahmoudi, E., Faneer, K., & Benamor, A. (2016). Novel graphene-zinc iron oxide composite to enhance ultrafiltration

membrane performance for water treatment and desalination. Paper presented

at the Qatar Foundation Annual Research Conference Proceedings.

Baig, N., Sajid, M., &

Saleh, T. A. (2019). Graphene-based adsorbents for the removal of toxic organic

pollutants: A review. Journal of Environmental

Management, 244, 370-382.

Bolto, B., Zhang, J., Wu,

X., & Xie, Z. (2020). A Review on Current Development of Membranes for Oil

Removal from Wastewaters. Membranes, 10(4),

65.

Chung, Y. T., Mahmoudi, E.,

Mohammad, A. W., Benamor, A., Johnson, D., & Hilal, N. (2017). Development

of polysulfone-nanohybrid membranes using ZnO-GO composite for enhanced

antifouling and antibacterial control. Desalination,

402, 123-132.

Faneer, K. A., Rohani, R.,

& Mohammad, A. W. (2016). Polyethersulfone Nanofiltration Membrane

Incorporated With Silicon Dioxide Prepared by Phase Inversion Method for

Xylitol Purification. Polymers and

Polymer Composites, 24(9), 803-808.

Fujioka, T., & Nghiem,

L. D. (2013). Modification of a polyamide reverse osmosis membrane by heat

treatment for enhanced fouling resistance. Water

Science and Technology: Water Supply, 13(6), 1553-1559.

Hamid, N., Ismail, A. F.,

Matsuura, T., Zularisam, A., Lau, W. J., Yuliwati, E., & Abdullah, M. S.

(2011). Morphological and separation performance study of polysulfone/titanium

dioxide (PSF/TiO 2) ultrafiltration membranes for humic acid removal. Desalination, 273(1), 85-92.

Ismail, A. F., Khulbe, K.

C., & Matsuura, T. (2015). Gas separation membranes. Switz. Springer, 10, 978-973.

Kumar, P., Sharma, N.,

Ranjan, R., Kumar, S., Bhat, Z., & Jeong, D. K. (2013). Perspective of

membrane technology in dairy industry: A review. Asian-Australasian Journal of Animal Sciences, 26(9), 1347.

Mahmoudi, E., Ng, L. Y.,

Ba-Abbad, M. M., & Mohammad, A. W. (2015). Novel nanohybrid polysulfone

membrane embedded with silver nanoparticles on graphene oxide nanoplates. Chemical Engineering Journal, 277, 1-10.

Rao, G. P., Lu, C., &

Su, F. (2007). Sorption of divalent metal ions from aqueous solution by carbon

nanotubes: a review. Separation and

Purification Technology, 58(1), 224-231.

Rao, R. A. K., Singh, S.,

Singh, B. R., Khan, W., & Naqvi, A. (2014). Synthesis and characterization

of surface modified graphene–zirconium oxide nanocomposite and its possible use

for the removal of chlorophenol from aqueous solution. Journal of Environmental Chemical Engineering, 2(1), 199-210.

Safarpour, M., Khataee, A.,

& Vatanpour, V. (2015). Effect of reduced graphene oxide/TiO2 nanocomposite

with different molar ratios on the performance of PVDF ultrafiltration

membranes. Separation and Purification

Technology, 140, 32-42.

Shanmugam, K. (2022). Spray

coated cellulose nanofiber laminates on the paper to enhance its barrier and

mechanical properties. Journal of

Sustainability and Environmental Management, 1(1), 10-17.

Shannon, M. A., Bohn, P.

W., Elimelech, M., Georgiadis, J. G., Marinas, B. J., & Mayes, A. M.

(2010). Science and technology for water purification in the coming decades. Nanoscience and technology: A collection of

reviews from nature Journals, 337-346.

Teow, Y., & Solihuddin,

M. (2020). Process synthesis and optimization of SiO2/PVDF mixed-matrix

membrane for oil-water emulsion separation. Paper presented at the IOP Conference Series: Earth and

Environmental Science.

Wei, J., Vo, T., &

Inam, F. (2015). Epoxy/graphene nanocomposites–processing and properties: a

review. RSC Advances, 5(90),

73510-73524.

Wu, H., Tang, B., & Wu,

P. (2014a). Development of novel SiO2–GO nanohybrid/polysulfone membrane with

enhanced performance. Journal of Membrane

Science, 451, 94-102.

Wu, H., Tang, B., & Wu,

P. (2014b). Development of novel SiO 2–GO nanohybrid/polysulfone membrane with

enhanced performance. Journal of Membrane

Science, 451, 94-102.

Yeh, T.-F., Cihlář, J.,

Chang, C.-Y., Cheng, C., & Teng, H. (2013). Roles of graphene oxide in

photocatalytic water splitting. Materials

Today, 16(3), 78-84.

Zhang, R., Liu, Y., He, M.,

Su, Y., Zhao, X., Elimelech, M., & Jiang, Z. (2016). Antifouling membranes

for sustainable water purification: strategies and mechanisms. Chemical Society Reviews, 45(21),

5888-5924.

Zhu, X., Loo, H.-E., & Bai, R. (2013). A novel membrane showing both hydrophilic and oleophobic surface properties and its non-fouling performances for potential water treatment applications. Journal of Membrane Science, 436, 47-56.

|

|

©

The Author(s)

2022. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Related Article: Spray Coated Cellulose Nanofiber Laminates on the Paper to Enhance its Barrier and Mechanical Properties |